FCCU Boltless Slide Valves

Designed to outperform industry standards for safety, performance and reliability

TapcoEnpro Slide Valves are designed for rigorous operating conditions. Originally designed for the tough specifications of the iron ore industry, the TapcoEnpro Boltless valve is able to withstand 1650°F (900°C) and 710 PSI (49 Bar) differential pressure. With these rigorous design specifications, the TapcoEnpro slide valve is able to offer outstanding performance in FCCU service as well.

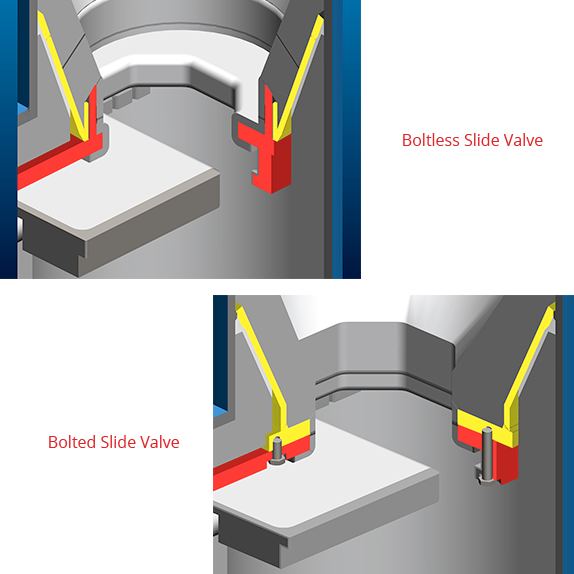

In 1998, TapcoEnpro introduced the Bolt-Less SlideValve™ design to solve a maintenance issue that had troubled refiners for decades. Our Bolt-Less SlideValve™ Design is the most important innovation yet when it comes to eliminating excessive downtime due to bolt failure.

Preventing premature valve failure has been a primary concern of TapcoEnpro. Our Bolt-Less SlideValve™ design eliminates the loading on the internal bolts that leads to deterioration and eventual failure of the valve. Since bolts are never placed in tension, you never have broken bolts inside the valve body. The orifice plate, disc and guide assembly carries the entire internal loading of the valve. The cross-sectional area of the guides holds the disc in place. The Bolt-Less slide valve achieves approximately 8 times the effective stress area of conventional bolting. Additionally, machined surfaces that mate together require no gasket seating and eliminate resurfacing, reworking or retapping of holes in the seat plate caused by bolting problems.

Boltless Slide Valve Advantages

- Boltless orifice / guide assembly is more robust and eliminates guide and orifice plate bolting.

- Forces created by the operating differential and support of the slide valve internals produce lower stress in the unitized connection than conventional guide to orifice bolting.

- Loads are transferred to the internal support cone and produce a lower stress across the assembly rather than high stress in the conventional orifice to seating plate bolting.

- Internal design cold set tolerances are preset and not be disturbed by handling or field installation.

- Positive seal between seating plate and orifice plate protects against by-pass or flow erosion.

- Seal between guides and seating plate eliminated.

- Replacement of internals during a turnaround with Boltless design accomplished in less time.

- Eliminate broken bolting during disassembly due to exposure to high operating temperatures.

- Field welding and machining of gasket surfaces and tapped bolt holes is eliminated.

The TapcoEnpro engineering team is constantly re-inventing FCCU flow control and was the first company to develop slide valves that resist failure even under the most extreme operating conditions. The innovative design is engineered to eliminate the loading on the internal bolting that leads to deterioration and eventual failure of the valve.