Digital Valve Controllers

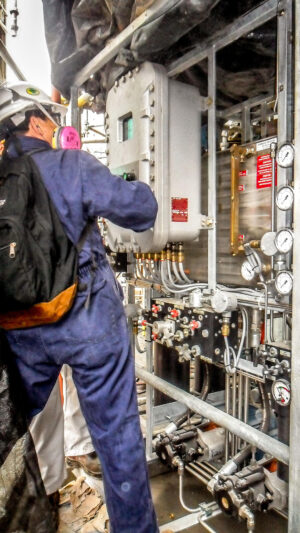

Providing total flexibility throughout design and manufacture to meet specific needs in the refinery.

Our controllers provide dependable service in major refineries throughout the world. They can be customized to your specifications and are available to control a variety of valve types including slide, plug, butterfly, diverter, angle, globe and gate. You’ll find us on the approved supplier list of major engineering firms, processing companies and refineries everywhere.

Pioneers in Hydraulic Positioning Systems

The Digital Valve Loop Controller (DVLC)™ serves as a valve positioner with control loop and alarms, while the Smart Valve Controller (SVC)™, in addition to valve position control, extends its capabilities to include hydraulic power unit and associated equipment control, providing a more comprehensive system solution.

Specialized Control Solutions

The DVLC and SVC are purpose-built control systems that do not rely on PLC-based architectures. We understand that some refineries prefer to avoid additional PLCs as basic process controllers. However, rest assured, we are also a trusted supplier of PLC control systems for those who favor this approach. For more information on our PLC Control Systems, see plc-based-controller.

Digital Valve Loop Controller (DVLC)™

Our Next Generation Enhancement from Analog to Digital

The DVLC™ is a direct upgrade for the TA-2000 Analog Controller. This next generation controller has User Interface Based Set-up and Calibration, so no special tools or software is required.

Tailored Operation

Configure DVLC for valve-specific operations, providing flexibility to adapt to diverse industrial requirements.

User-Friendly Interface

Empower operators with an intuitive Graphic User Interface that enhances ease of use and system understanding.

Simplified Set-up and Calibration

Effortlessly set up and calibrate with a user interface-based process - no special tools or software required

Backup and Export Capabilities

Ensure system integrity with backup calibration and setup import/export functions via removable storage devices, minimizing warehouse spares requirement

Compliance Beyond Standards

DVLC meets and exceeds the requirements and specifications of licensors, industry standards, and best practices.

Cutting-Edge Digital Control

Unleash the power of true digital control for FCCU and Flexi-Coker applications (Slide / Butterfly / Plug Valves)

Rugged Compact Design

Engineered for On-Skid or Field mounting, ensuring a robust solution that reduces installation costs.

Millisecond Precision

Achieve unparalleled control and valve positioning with a lightning-fast millisecond response rate.

Enhanced Reliability with Standard Redundant Power Supplies

Ensure uninterrupted operations with built-in redundant power supplies

Flexible Transmitter Configurations

Configure for 1oo1 or 1oo2 valve position transmitters to meet the specific needs of your operation.

Data and Event Logging

Benefit from on-board data and event logging for comprehensive operational insights and analysis.

Smart Valve Controller (SVC)™

Introducing the Smart Valve Controller (SVC) - the next generation of the proven-in-use TA-3000 digital valve controller, with nearly two decades of field-tested reliability.

One of the True Digital Controllers for FCC and Flexi-Coker applications for Slide, Plug and Butterfly Valves

Redundancy for Reliability

The SVC comes with redundancy, including hot-swappable processors and redundant power supplies. This redundancy enhances system reliability and minimizes the risk of downtime.

Tailored Operation

Configure DVLC for valve-specific operations, providing flexibility to adapt to diverse industrial requirements.

Rugged Design

The SVC boasts a rugged and compact design suitable for both on-skid and field mounting. This not only reduces installation costs but also ensures the controller can withstand the challenging conditions often encountered in harsh refinery environments.

Micro-Second Response Rate

When precision is crucial, the SVC delivers with a micro-second response rate. This ensures precise control and accurate valve positioning, even in rapidly changing conditions.

Configurable Valve Position Transmitters

Flexibility is key, and the SVC can be configured for 1oo1, 1oo2, or 2oo3 valve position transmitters, allowing you to choose the level of redundancy that suits your application.

Built-In Diagnostics and High-Speed Data Logging for Enhanced Insight

The system's built-in diagnostics and high-speed data logging offer critical insights into system health, simplifying maintenance. This advanced feature enhances troubleshooting capabilities, providing an efficient path to optimal performance.

Seamless Communication

Modbus communications facilitate integration with your existing systems, enhancing overall operability and system status visibility.

Operator-Friendly Interface

The SVC comes equipped with a user-friendly graphic user interface, simplifying interaction with the system. Set-up and calibration can be performed without the need for special tools or software.

Data Management

Data management is a breeze with back-up calibration and set-up import/export functions via removable storage devices. This ensures that you can easily transfer and safeguard critical system configurations, calibrations, and data.

Meeting and Exceeding Industry Standards

Rest assured that the SVC meets or exceeds the requirements and specifications of licensors, industry standards, and best practices. It's a solution you can trust for your critical operations.

Tailored Solutions for Your Unique Needs

At TapcoEnpro, we understand that every application is unique. Our Smart Valve Controller (SVC) system is custom-tailored to suit your individual needs. Whether you require controls only or a combination of controls and actuators, we have the expertise to provide the ideal solution for your specific requirements.

Contact Us

Ready to experience the precision, reliability, and flexibility of the DVLC or SVC? Contact our team today to discuss your needs, request a quote, or receive more information about our customized solutions.

Our controls are available on your choice of skids; single, dual or multi-control. Actuators can be Electro-Hydraulic, Electric or Pneumatic with analog or digital control for rotary or linear actuation. Our retrofit system offers full response hydraulic control from your existing hydraulic power supply system. Custom tailored to suit individual needs, the system is available as controls only or controls and actuators utilizing existing hydraulic power systems.

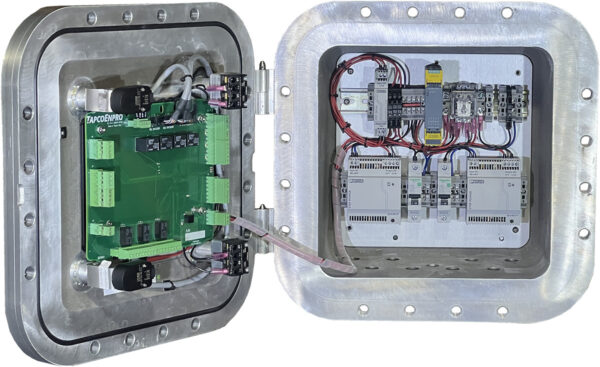

The electronics enclosure contains the heart of the control system. Access is not required for calibration, only for replacement of components, if ever necessary. All trouble shooting of the overall system can be completed by referring to the visual display.