Two Port Flue Gas Diverter Valves

Custom built diverter valves, designed to the individual unit requirements, for precise diversion of flue gas flow.

TapcoEnpro’s Diverter Valve is designed for accurate and consistent diversion of the flue gas flow to the CO boiler or stack. There is one inlet port and two outlet ports; one connected to the CO boiler and the other connected to the stack. The flue gas from the inlet port flows to the CO boiler and the stack port is closed by a rotating disc.

Two Port Diverter Valves are available is several designs depending on the process design licensor, accessibility to existing diversion point and weight restrictions. Styles include Pendulum, Linear, Butterfly and Flip-Flop Valves.

The Pendulum style valve is the most commonly used design which operates by sliding a disc from one port to the other creating the diversion of flow. The Linear type valve requires the stem to be directly in the flow path and is not widely used in new applications.

In retrofit applications, most all valves are replaced in kind unless weight becomes a factor. The Butterfly Diverter Valve is typically half to one third the weight of a linear or pendulum valve and is considered a reliable application.

All valves are available in either cold shell or hot shell design and operation of the valve can be with and electro-hydraulic actuator system, electric motor or pneumatic since the action is open close and not flow control.

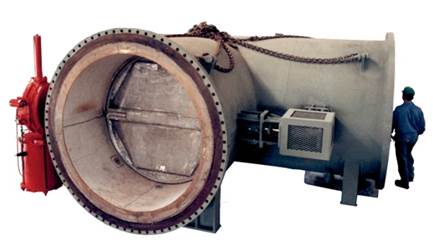

Butterfly Diverter Valve

Pendulum Diverter Valves

The design concepts developed for the TapcoEnpro Two Port Flue Gas Diverter Valve are the results of both empirical and analytical data gained from over a half century of service in rigorous industry applications.