FCCU Fractionator Isolation Valves

See how the TapcoEnpro Isolation Valve provides a safer environment when isolating the reactor from the fractionator resulting in reliable FCC operations and beneficial cost saving during turnarounds.

An FCCU is expected to operate without interruption for 3 to 6 years. Maintenance requirements include isolating the reactor from the fractionator by placing a physical blind in the reactor overhead line. The manual insertion and removal of the blind flange is one of the most threatening operations in the refinery. There is a need for a safe operator environment for isolation of a hazardous process by eliminating personnel from the operation and emissions of hydrocarbons to the atmosphere.

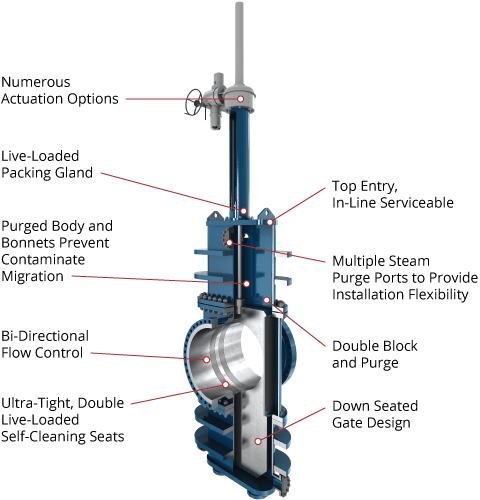

- Smallest Dimensional Footprint

- Top Entry In-Line Serviceable

- Lowest Steam Consumption

- Safer Valve Design

Our Solutions

Industry Challenges Solved

- Provides greater opportunity for safe isolation of vessels

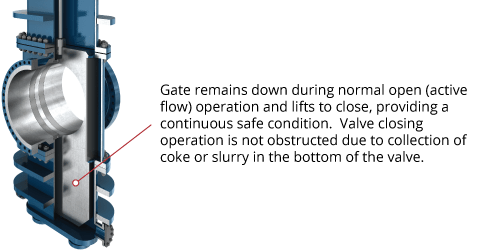

- 100% process isolation with Double Block and Purge technology

- Simple, robust and reliable design with a single moving component

- True mechanical gate position indication and positive lockout mechanism

- Engineered specifically for the reactor overhead line operational conditions and sizes

- Low maintenance costs

Industry Challenges Solved

Watch our video

Watch our video